Crank Shaft IH Coil Technologies

Fuji-Denshi Induction Coil Manufacturing Philosophy.

Our philosophy is to design the optimal inductor shape based on the customer’s required quench-hardening quality and expected hardening conditions. Each copper part is produced using the most suitable manufacturing method, then assembled into a single inductor. Rather than shifting from hand-made to 3D-printed inductors, FD has adopted each method in chronological order to improve performance and reliability.

Hand-Made Copper Components

The hand-made method of coil building relies on bending copper pipes by hand, a process that emphasizes craftsmanship and experience.

- Hand-made coil building involves bending copper pipes by hand.

- Coils are shaped with precision to meet hardening requirements.

- Advantages: time and cost savings for simpler designs.

- Limitation: challenging for complex shapes, requiring expertise and patience for consistency.

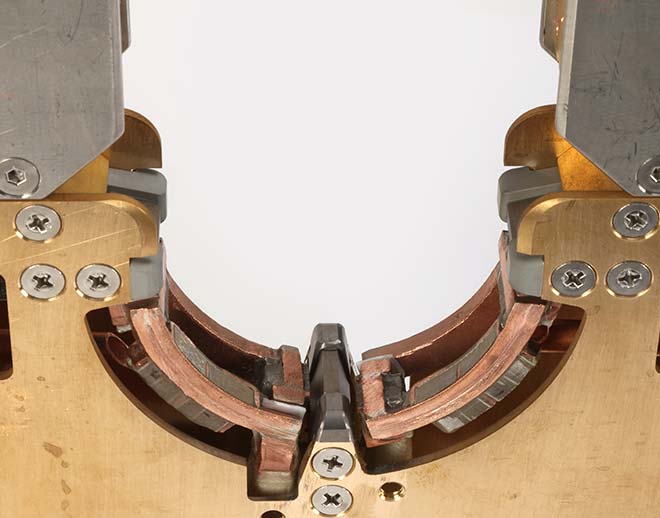

Machining Copper Components

Machining coils uses advanced technology to create induction coil parts greater precision and complexity than hand-made coils.

- Enables intricate shapes and exact tolerances for consistent results.

- Offers high flexibility, accuracy, and performance.

- Drawback: more time- and cost-intensive than hand fabrication.

- Best for parts where complexity and reliability are priorities over speed.

Lost-Wax Copper Components

Lost-wax casting produces precise, intricate copper parts with minimal waste.

- Reduces excessive machining and lowers production costs.

- Combines traditional craftsmanship with strict process control.

- Skilled technicians ensure accuracy from wax model to final casting.

- Limitations: long lead time and low flexibility.

- Less suited for rapid design changes or custom adjustments.

3D Printed Copper Components

Additive manufacturing uses 3D printing for precise copper parts with minimal labor.

- Shorter lead times compared to lost-wax casting.

- Eliminates vulnerable areas (e.g., brazed joints) for greater durability and reliability.

- Skilled operators and advanced equipment ensure consistent quality.

- Drawback: high raw material costs.

- Less cost-effective for large-volume production.