Automotive IH Equipment

Advancing Automotive Case Hardening Technologies Over 65 Years.

Fuji-Denshi US is pleased to bring decades of IH case hardening experience to North America. With proven technologies and a list of major OEM clients, we are confident that Fuji-Denshi US Automotive IH Equipment will satisfy a wide range of center shaft case hardening requirements.

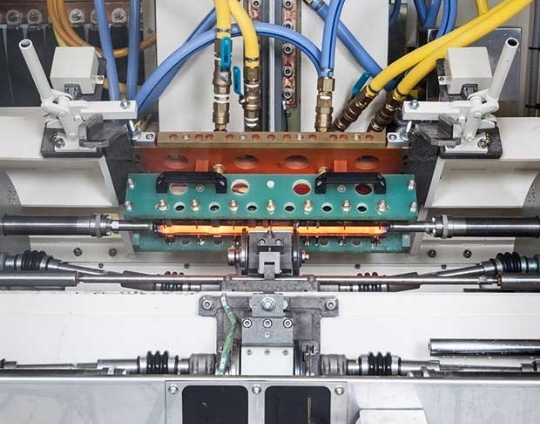

Driveshafts

Even Casing

- Semi-open coil shaped to workpiece generates axial current for uniform case depth.

- Enables deep fillet hardening.

- One-shot hardening boosts thermal efficiency, reduces power use by ~50% per part, and minimizes warpage.

Hollow Shafts Requiring Shallow Hardening

- Requires high frequency, high output, short heating time, and rapid, even quenching.

- Preserves base metal while hardening thin-walled areas.

- Fuji Electronics has extensive expertise in this process.

Pinion Gears

High Frequency for Power Reduction

- Switching from carburization to IH hardening reduces power consumption by up to 80%.

Minimal Warpage

- Only the necessary areas are hardened, which minimizes post-hardening warpage.

One-Shot Hardening for Continuous Casing

- One-shot hardening produces a continuous casing, even in difficult areas such as steps and grooves. Unlike scan hardening, it avoids overheating in large steps.

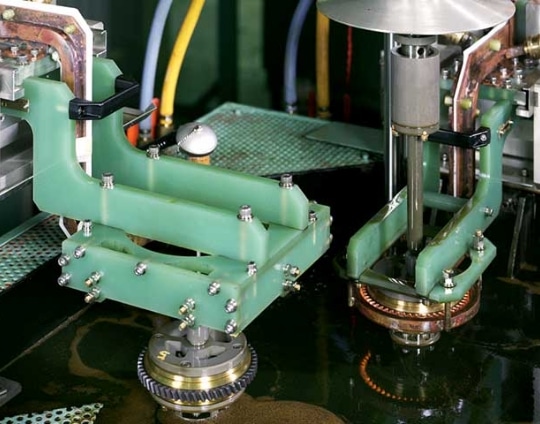

Constant Velocity Joints (CVJ)

One Converter for Multiple Hardening Locations

- Multi-frequency converter switches between three frequencies.

- Capable of hardening ball grooves, roller grooves, spline grooves, and shafts.

Long-Lasting Multi-Turn Coils

- Spiral coils with 4+ turns provide ideal casing for groove sections.

- Durable for over 200,000 shots.

Cooling Technology to Prevent Soft Spots

- Suppresses internal air during cooling.

- Prevents soft spots in groove sections.

Concentrators

- Dissipate excess heat at groove end faces.

- Optimized shape/material prevent cracking and melting.

Precision Gears and Contours

Contour Hardening

Three-step process for precision results:

- 1. Low-frequency preheating reaches target depth.

- 2. Ultra-short, high-frequency, high-power heating hardens surface layer.

- 3. Controlled immersion cooling locks in hardness.

Especially effective for small-module gears.

Benefits: uniform hardness, minimal distortion, extended gear life.

Crankshafts

Low-Warpage Hardening (Flat and Fillet Supported)

A semi-open coil hardens while tracking the rotating workpiece, minimizing warpage.

Power Reduction System

Case depth is adjusted by varying power according to the rotational angle of the workpiece, ensuring consistent hardening between the pin top side and balance weight side. The post-polishing core is precisely rounded.

Small Cranks

We provide coils and thin disk transformers capable of achieving a 10.5 mm hardening width.

Trend and Power Monitoring Systems

Workpiece-to-coil positioning greatly affects quality. Fuji Electronics monitors this relationship and hardening conditions with our Trend Monitoring System, while the Power Monitoring System tracks total power input.

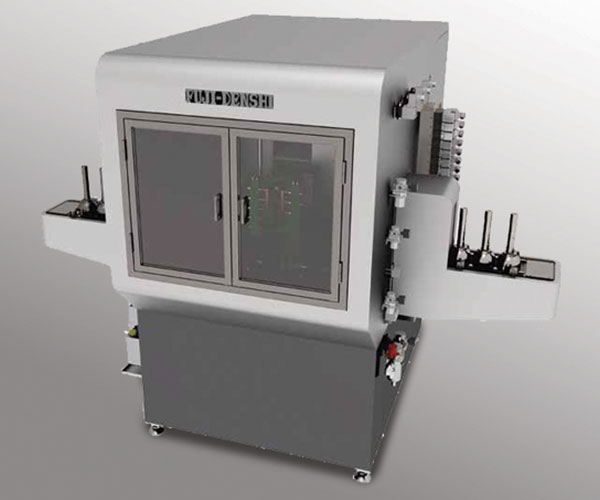

Compact Equipment

To meet gantry height limits and shipping container size restrictions, our equipment has been downsized to about one-third the volume and a height of 2000 mm.

Camshafts

Eccentric Hardening

The coil moves eccentrically with the rotating cam, keeping top and bottom gaps constant to form an even casing. This prevents overheating cracks on the cam top and reduces grinding after processing.

Minimal Warpage

A proprietary concentrator ring limits unnecessary journal heating, minimizing warpage.

Coil Position Auto-Adjustment (Optional)

Cam conditions and coil or transformer positions can be automatically adjusted for different cam models.