Commercial & Industrial Vehicle IH Equipment

Construction, Agriculture, Transport.

Industry Counts on Fuji-Denshi US for Heavy Equipment IH Solutions.

Fuji-Denshi US industrial IH equipment delivers fast, efficient, and precise hardening for construction, agriculture, and transport parts. One-shot and 360° treatments cut cycle time and energy use while preventing soft zones and warpage. Advanced quenching and heating ensure even casing, and compact, versatile machines handle large, varied components with consistent, high-quality results.

Idlers and Rollers

One-Shot Hardening of Both Ends

- Hardens both ends simultaneously with semi-open coils.

- Reduces cycle time and eliminates the need to rotate heavy workpieces.

- Lightens operator workload.

One-Shot Hardening Prevents Soft Zones

- Eliminates soft zones common in traditional scan hardening.

- Improves wear resistance.

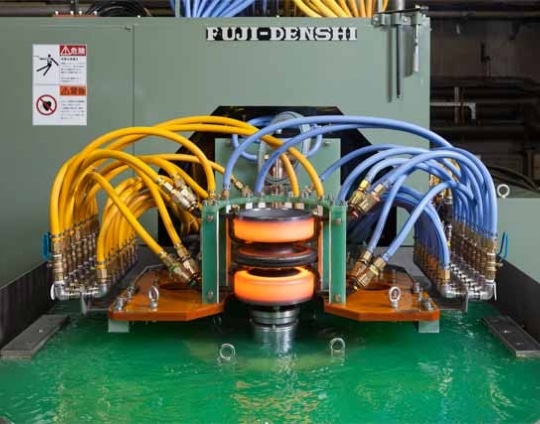

Heating and Dip-Spray Quenching for Even Casing

- Combines pre-heating, main heating, and dip-spray quenching.

- Ensures even casing and prevents cracking in idler rollers.

Slewing Bearings and Large Gears

360° One-Shot Hardening

- Hardens entire outer or inner circumference in one shot.

- Reduces treatment time by ~80% and electricity use by 50-65%.

Dip-Spray Quenching

- Submerges and sprays workpiece for uniform cooling.

- Minimizes warpage and uneven hardening.

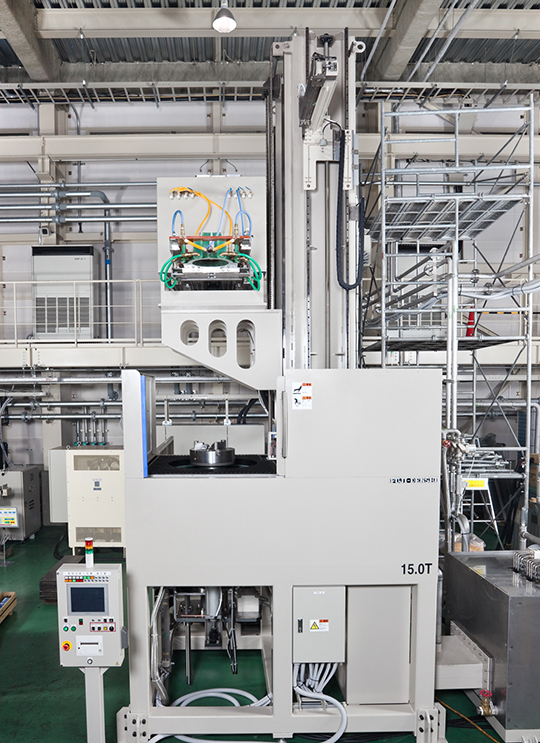

Compound Hardening Equipment for Large Ship Parts

Coil Movement for Compact Design

- Matching unit moves with coil while maintaining steady power.

- Enables compact equipment installation without a pit.

Varying Large Parts Hardened by Single Machine

- Compound equipment handles dip-spray quenching and vertical scan hardening.

- Accommodates widely varying shapes, e.g., piston rods and exhaust valve seats.